Polymer Modified Bitumen and Crumb Rubber Modified Bitumen is use in various road paving application.

AMT TECHNO’s Bitumen Modification plant can be useful to produce verity of product as per your requirement. PMB/CRMB Equipment is mainly produce Polymer Modified Bitumen (PMB), Crumb Rubber Modified Bitumen (CRMB), APP Modified Bitumen, SBS Modified Bitumen and many more Road and Roofing application.

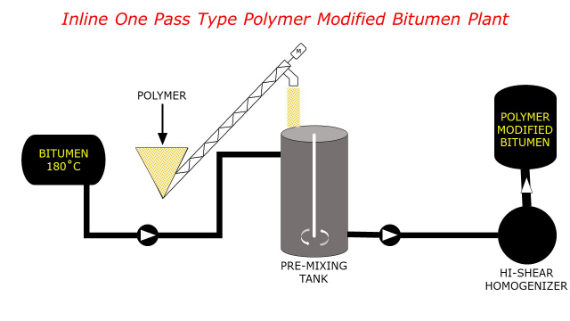

AMT TECHNO’s Fully Automatic Inline One Pass Type PMB/CRMB Plant is useful to customers who have large requirement market. In Inline One Pass System, bitumen directly come from the storage and dose to the 1,000 litters premixing tank by pump, premixing tank is equipped with agitator for premix bitumen, at same time polymer or crumb rubber is dose in premixing tank by screw conveyor both ratio are controlled by PLC based control panel. The other side one pump connected to premixing tank outlet, it is dosing bitumen and polymer or crumb rubber to Hi Shear Homogenizer. Pump is controlled by Level Transmitter which is installed in the premixing tank.

Advantage of Inline One Pass system

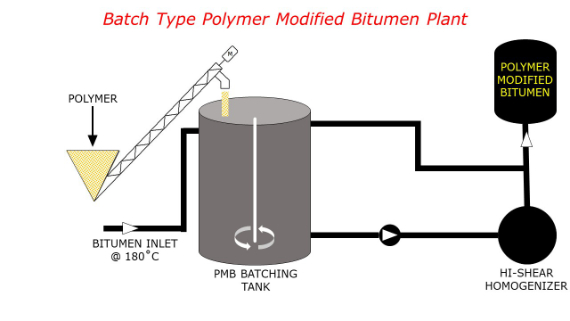

AMT TECHNO’s Manual Batch Type POLYMER MODIFIED BITUMEN (PMB PLANT)/CRMB PLANT is small setup and very useful to customer who does not want to manufacture large verity of Modified Bitumen. Batch system is also contains premixing tank but capacity is 5,000 litters to 10,000 litters, premixing tank is equipped with agitator for premix. Bitumen is dosed in the premix tank by manually controlled pump and Polymer or Crumb rubber is manually dosed by manually controlled screw conveyor as per the recipe. Time of premixing tank blending is deepened as per the recipe. One manually controlled pump is connected at premixing tank outlet, after preparation of batch, pump is dose the Bitumen and polymer or crumb rubber to Hi Shear Homogenizer. Also there is one option to mount premixing tank on load cell for precise the dosing of Bitumen and Polymer or crumb rubber.

Advantage of Batch System