Bitumen Emulsion are widely use in road construction application as a binder, surface dressing, priming etc. Bitumen Emulsion is Oil in Water type of emulsion where bitumen is dispersion in water.

AMT TECHNO’s Bitumen Emulsion Plant is equipped with AMT Hi Shear Colloidal mill which is especially designed for ensure maximum dispersion of bitumen in water. We are mainly manufacture and supply two type of equipment for producing Bitumen Emulsion.

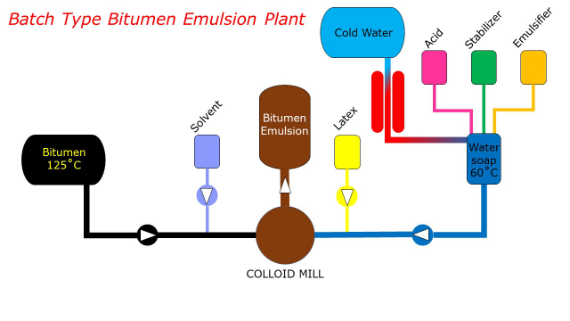

AMT TECHNO’s Automatic batch type bitumen emulsion plant is small and very useful to customer who does not want to manufacture large verity of Bitumen emulsion. But they can still have the option to produce Cationic, Anionic, Modified Bitumen Emulsion and Micro surfing Emulsion. In batch system there is a non-metallic tank which have agitator designed to mix the water and chemicals mainly Acid, Stabiliser and Emulsifier. After preparation of water soap plant can run and produce the Bitumen Emulsion as per your required recipes. At same time Bitumen is directly coming from the storage and solvent will dose in the bitumen line, so it gives the great flexibility to customers and save the time to preparation of bitumen batch.

Advantage of Batch System

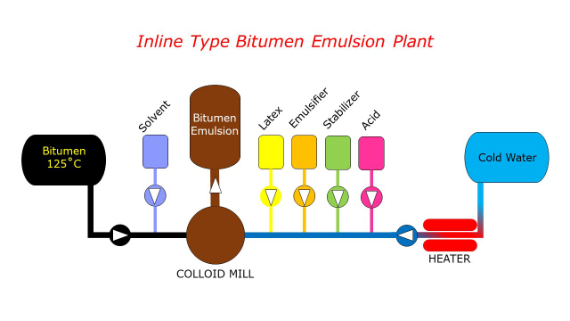

AMT TECHNO’s Fully Automatic Inline Type Bitumen Emulsion Plant is useful to customers are have large market. This equipment is fully automated system which is give continues output of your desired Bitumen Emulsion. Inline plant is very flexible to change the grades of one to other because the chemicals are dosed in the water line so there is no need to prepare water soap batches, that’s why inline system is very flexible to change the grade form one to another.

Advantage of Inline System